The Importance of Camshaft Optimization

Agricultural diesel equipment relies on powerful engines to perform heavy-duty tasks like plowing, harvesting, and transporting goods. Camshaft optimization can significantly improve engine efficiency, durability, and fuel economy. The camshaft controls the timing and movement of intake and exhaust valves, directly impacting engine performance.

Engineers carefully design camshaft profiles to ensure maximum power output while maintaining reliability. Properly tuned camshafts improve fuel combustion, reducing waste and emissions. Adjusting valve timing can also enhance low-end torque, essential for heavy-load applications. By optimizing camshaft profiles, farmers can achieve better engine performance and longevity.

How Camshaft Profiles Affect Airflow and Combustion

The camshaft profile directly influences an engine’s air intake and exhaust cycle. A high-performance camshaft opens and closes valves at precise moments to maximize airflow. Agricultural engines operate under varying loads, requiring flexible camshaft designs. An ideal profile balances power, efficiency, and durability.

Shorter valve durations provide better low-end power, while longer durations improve high-speed performance. A well-optimized camshaft ensures consistent power delivery for demanding farming tasks. This balance helps agricultural machinery perform efficiently under heavy workloads, reducing fuel consumption and emissions.

The Role of Custom Camshaft Grinding

Custom camshaft grinding allows engineers to fine-tune performance characteristics. Small adjustments in lift, duration, and overlap significantly impact engine behavior. Increasing valve lift enhances airflow, boosting power output. However, excessive lift may strain engine components, reducing lifespan.

Adjusting valve timing can optimize combustion, improving fuel efficiency. Engineers also consider camshaft material composition for durability. Heat-treated steel or billet camshafts provide superior strength for high-torque applications. Precision engineering in camshaft design ensures engines perform efficiently under agricultural conditions, making custom camshafts an essential upgrade for modern diesel equipment.

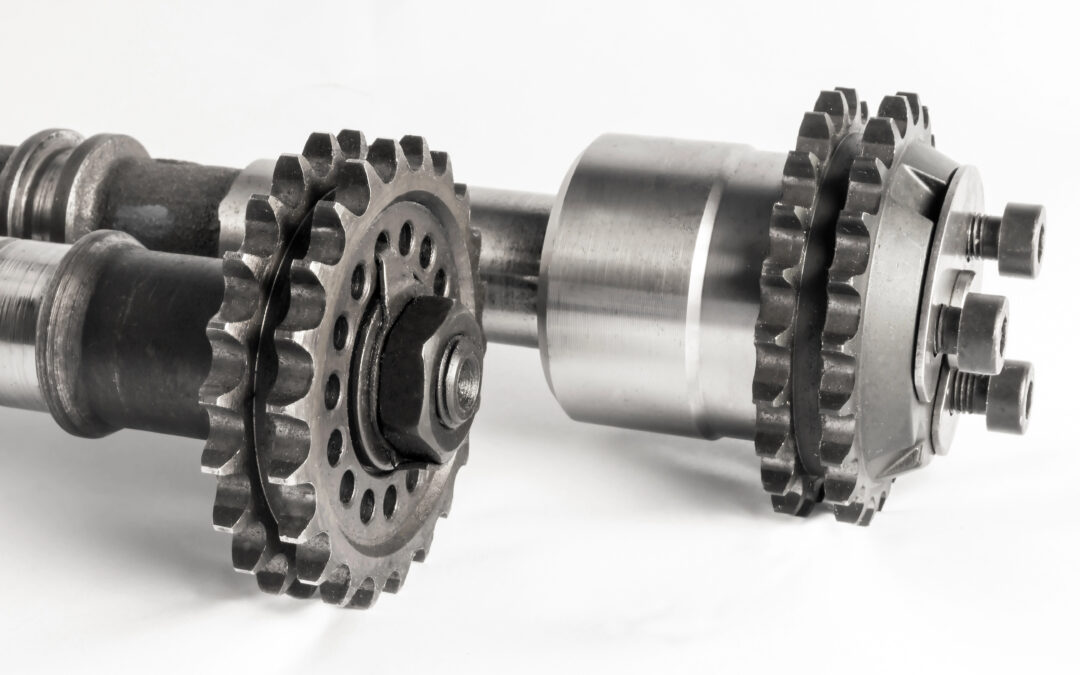

Integrating Variable Valve Timing (VVT) Technology

Variable valve timing (VVT) technology offers dynamic camshaft control. Traditional fixed camshaft profiles work well but lack adaptability. VVT systems adjust valve timing based on engine load and speed. This technology improves fuel efficiency by optimizing airflow at different RPM ranges.

Agricultural engines benefit from VVT by maintaining power under changing conditions. For example, VVT increases low-end torque for plowing but enhances top-end power for transport. Integrating VVT in diesel engines can reduce fuel consumption while maintaining high performance. This adaptability makes agricultural machinery more efficient and cost-effective.

Preventing Camshaft Wear and Tear

Camshaft wear and tear can reduce engine efficiency over time. Continuous use under high loads causes cam lobes to degrade. Regular maintenance, including lubrication and inspection, prolongs camshaft life. Upgrading to high-quality camshafts reduces the risk of premature wear.

Performance coatings, such as nitriding or phosphate treatments, improve surface hardness. These coatings reduce friction and extend component lifespan. Proper camshaft maintenance ensures consistent power delivery and operational efficiency. Farmers benefit from reduced downtime and lower maintenance costs, keeping their equipment running smoothly during critical farming seasons.

Enhancing Performance While Reducing Emissions

Balancing performance with emissions control is another crucial aspect of camshaft optimization. Modern emission regulations require engines to minimize pollutants. Camshaft tuning helps achieve cleaner combustion, reducing nitrogen oxides and particulates. Optimized valve timing ensures complete fuel burn, lowering emissions.

EGR (Exhaust Gas Recirculation) systems work better with precisely timed valve events. Camshaft refinements can improve after-treatment system efficiency. By optimizing camshafts for emissions control, agricultural equipment meets regulatory standards while maintaining performance. Cleaner engines contribute to sustainable farming practices and help protect the environment.

Selecting the Right Camshaft Profile for Agricultural Applications

Selecting the right camshaft profile requires careful consideration of operating conditions. Agricultural diesel engines differ from automotive engines due to their heavy-duty nature. A camshaft designed for high-speed racing differs from one optimized for low-RPM torque. Farmers should consult engine specialists when upgrading camshafts.

Custom profiles tailored to specific machinery needs yield the best results. Factors like engine displacement, fuel type, and workload influence camshaft selection. Choosing the right camshaft enhances efficiency, power, and equipment longevity. Investing in optimized camshafts leads to long-term benefits in agricultural operations, improving productivity and fuel savings.

Future Innovations in Camshaft Technology

As engine technology advances, new innovations in camshaft design are emerging. Advanced materials, such as carbon composites and reinforced alloys, are making camshafts stronger and lighter. Computer-aided design (CAD) software allows engineers to create precise camshaft profiles tailored for specific applications.

The use of electronic camshaft actuators, which replace traditional mechanical systems, provides even greater control over valve timing. These advancements will further enhance the efficiency and durability of agricultural diesel engines. As technology progresses, farmers can expect even more reliable and fuel-efficient engines for their agricultural machinery.

The Economic Benefits of Camshaft Optimization

Optimizing camshaft profiles provides financial benefits beyond fuel savings. Efficient engines reduce maintenance costs by minimizing wear and tear on other components. A properly designed camshaft decreases stress on pistons, crankshafts, and bearings, leading to extended engine life.

Farmers can maximize the return on their investment by upgrading to high-quality camshafts that improve performance and reliability. Additionally, increased fuel efficiency lowers operational expenses, allowing agricultural businesses to allocate resources to other areas. In a competitive industry, reducing costs while maintaining productivity can significantly impact long-term profitability.

The Role of Research and Development in Camshaft Technology

Continuous research and development (R&D) drive advancements in camshaft technology. Manufacturers invest in extensive testing to create camshaft profiles that offer the best balance of power, efficiency, and durability. Computational simulations and real-world testing help refine designs before implementation.

Agricultural machinery manufacturers collaborate with engineers to develop camshafts that meet the specific needs of modern farming. As new technologies emerge, ongoing R&D will ensure that future camshafts deliver even greater performance improvements. Farmers who stay updated on these innovations will benefit from the latest advancements in diesel engine efficiency and reliability.