Comparing diesel and petrol engine camshafts reveals significant differences that stem from each engine type’s operational characteristics and requirements. These differences are mainly due to the distinct ignition processes and performance demands of diesel and petrol engines. Here’s a comparison:

Material Strength and Construction

Diesel Engines

Diesel engines work really hard and create a lot of pressure inside. This is because they compress air much more before mixing it with fuel to make power. Because of this high pressure, every part of a diesel engine, especially the camshafts, needs to be super strong to not break or wear out quickly.

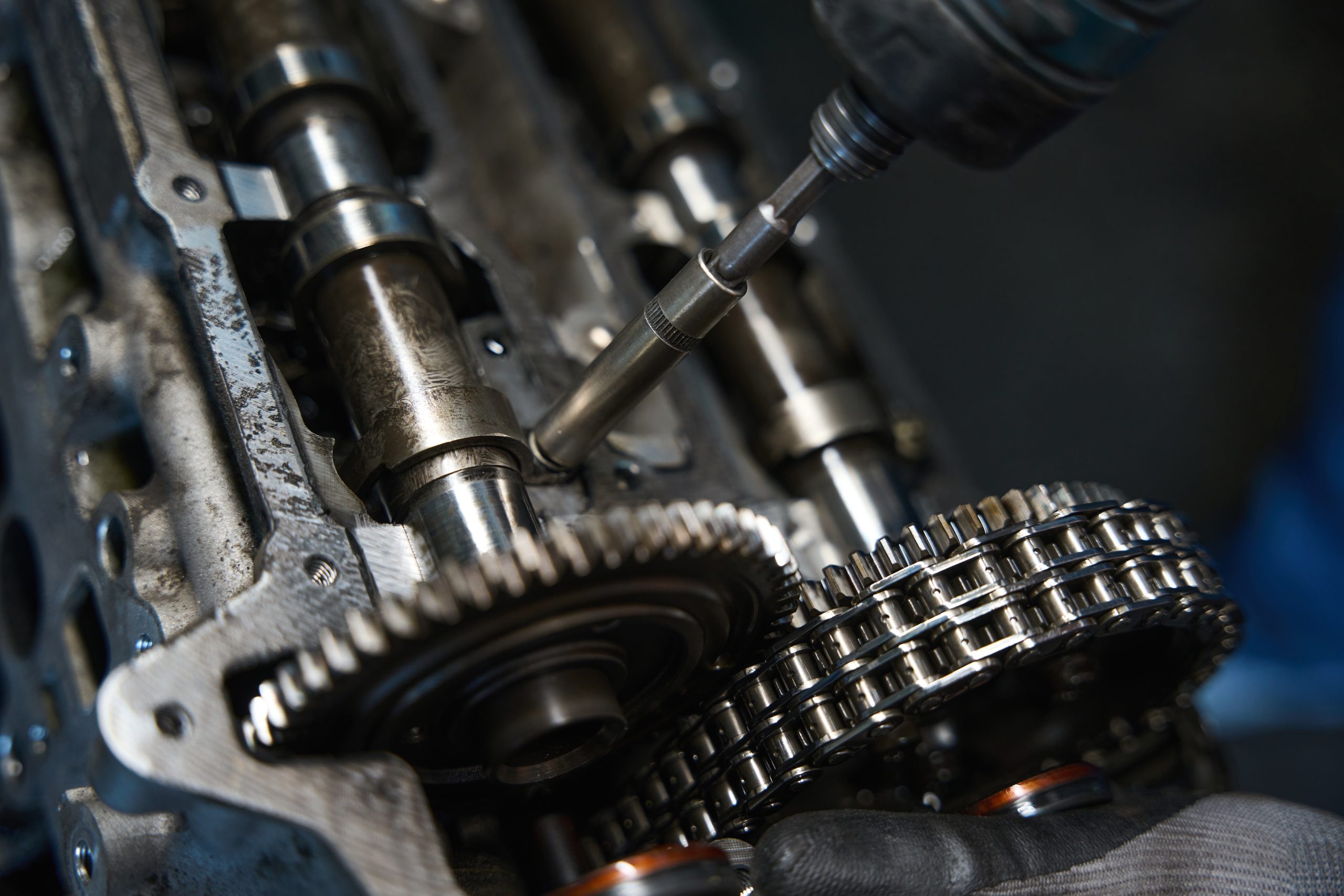

Camshafts are important parts that help open and close the engine’s valves at the right time. For diesel engines, these camshafts are made from special, very tough materials. This makes them able to handle the intense pressure and heat they’re exposed to every day.

They’re designed to be durable, meaning they’re built to last a long time and keep the engine running smoothly without problems. This focus on strength and durability helps ensure that diesel engines can do heavy work for years without major issues.

Petrol Engines

Petrol engines, while powerful, operate under less pressure than diesel engines. This difference affects how their parts, like camshafts, are made. Camshafts in petrol engines still need to be strong because they play a crucial role in opening and closing the engine’s valves to let air and fuel in and out.

However, since the pressure inside petrol engines is lower, the materials used for these camshafts can be slightly less heavy-duty compared to those in diesel engines. They are made from materials that are tough enough to handle the engine’s workload but don’t need to withstand the extreme conditions of diesel engines.

This balance ensures that petrol engine camshafts are durable and reliable, yet possibly lighter and less expensive to produce. The focus is on creating parts that provide good performance and efficiency while keeping the engine running smoothly.

By using materials that are strong but appropriately matched to the engine’s needs, manufacturers ensure that petrol engines are cost-effective and maintain good fuel efficiency.

Camshaft Design and Lobe Profiles

Diesel Engines

In diesel engines, the camshaft design and the shape of the lobes on it are very important. These lobes are the parts that push against the engine’s valves to open and close them at the right time. Because diesel engines work by compressing air very tightly and then injecting fuel, the way the lobes are shaped can really affect how well the engine runs.

The lobes are designed to make sure the air and fuel mix well and burn efficiently, which helps the engine produce more power without wasting fuel. This is especially important in diesel engines because they rely on this compression and burn process to work correctly. The design of the lobes also ensures that the engine runs smoothly and quietly, which can be a challenge with the high pressure inside diesel engines.

In addition, the lobe profiles have to match the diesel engine’s need for high torque at low speeds. Torque is what helps your vehicle start moving from a stop and pull heavy loads. Diesel engines are often used in trucks and equipment that need to do heavy lifting, so having the right camshaft design is crucial.

Manufacturers spend a lot of time testing and refining the shape and size of these lobes to get the best performance out of their engines. They use advanced computer programs to model how the air and fuel will flow through the engine and how it will affect performance and emissions.

Petrol Engines

In petrol engines, the camshaft and its lobe profiles play a crucial role in how the engine performs. These lobes are the parts of the camshaft that push the engine’s valves open and closed, controlling when air and fuel enter the engine and when exhaust gases leave.

Petrol engines use a spark to ignite the air-fuel mixture, so the timing of the valves opening and closing is really important for getting the most power and efficiency out of the engine. The shape and size of the camshaft lobes determine this timing. They’re designed to open the valves at the best moment to let in the right amount of air and fuel, and then to close them at the perfect time to maximize power.

Lobe profiles for petrol engines are often designed to help the engine run smoothly at high speeds, as petrol engines typically operate over a wider RPM range than diesel engines. This means the lobes need to be shaped in a way that allows for quick opening and closing of the valves, to support the engine’s ability to rev high and produce more power.

The design of these lobes also affects how the engine sounds, which is why some high-performance petrol engines have a distinctive roar that enthusiasts love. Manufacturers use advanced technology and lots of testing to create lobe profiles that offer a good balance between power, efficiency, and that desired engine sound.

Valve Timing Differences

Diesel Engines

Valve timing in diesel engines is important to their performance and efficiency. This is about deciding when the engine’s valves open and close during each cycle. Diesel engines compress air first, then inject fuel into this compressed air, which ignites due to high pressure and temperature.

These engines have valve timing that ensures air is brought into the combustion chamber at just the right moment, and exhaust gases are expelled efficiently. Getting the timing right helps diesel engines be more powerful and use fuel more efficiently, which is good for both performance and the environment.

Precise valve timing is required to manage the high pressures they operate under. This timing affects everything from how well the engine starts when it’s cold to how much power it can make and how much fuel it uses. If the timing is off, the engine might not run as smoothly, could produce more emissions, or might not be as powerful as it could be.

Engineers design diesel engines’ valve timing to get a good balance between power, fuel efficiency, and emissions. This often means opening the intake valves just a bit earlier or closing the exhaust valves a bit later than in petrol engines, to make sure the engine can breathe properly and maintain the high pressures needed for efficient combustion.

Petrol Engines

Valve timing is essential for petrol engines’ performance, impacting their power, fuel efficiency, and emission levels. n petrol engines, air and fuel are mixed before being ignited by a spark. The timing of when the engine’s valves open and close to let this mix in and out needs to be precise.

Petrol engines often rev higher than diesel engines, so their valve timing is designed to optimize performance at these higher speeds. This means the valves need to open and close quickly to match the engine’s fast pace, allowing it to breathe properly and make more power.

The valve timing in petrol engines is adjusted to ensure that the right amount of air and fuel mixture enters the combustion chamber at the perfect time. It also makes sure that exhaust gases are expelled efficiently right after combustion.

This precise timing helps the engine run smoothly and efficiently, using less fuel and producing less emissions; as well as making the engine more responsive. This means the car feels quicker and more powerful when you press the accelerator. Plus, good valve timing can reduce the engine’s wear and tear, helping it last longer.

Manufacturers use technologies like Variable Valve Timing (VVT) to adjust the valve timing while the engine is running. This tech adjusts the timing based on how fast the engine is going and how much power is needed. It’s like the engine tunes itself on the go for the best performance and fuel economy.

RPM Range Optimization

Diesel Engines

RPM (revolutions per minute) range optimization in diesel engines is all about making sure these engines perform best where they’re used most. Diesel engines are known for their strength and efficiency at lower speeds compared to petrol engines. This means they’re designed to give a lot of power and use fuel efficiently even when they’re not running very fast.

Diesel engines are great for vehicles and equipment that need to do heavy lifting or towing, like trucks and construction machinery. They provide strong performance without needing to rev high, which is also why they’re more fuel-efficient for these types of tasks.

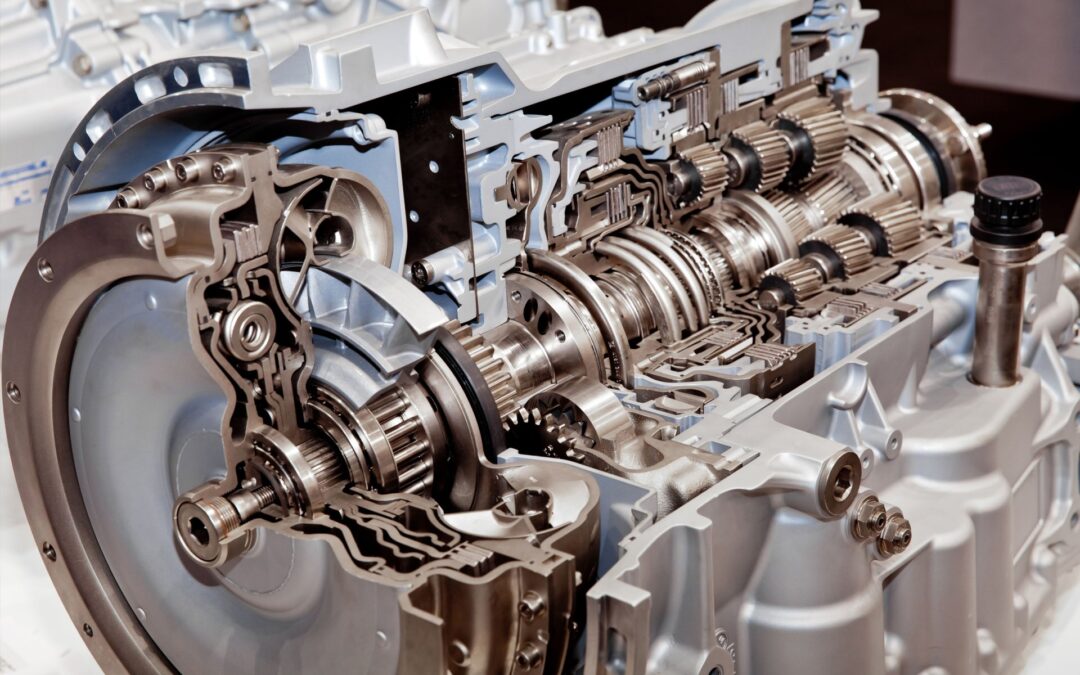

The design of diesel engines focuses on producing a high amount of torque – which is the force that gets things moving – at low to medium RPMs. Engineers work on various parts of the diesel engine, like the camshaft design and turbochargers, to make sure it delivers this power smoothly across a wide range of speeds, but especially where it counts the most, at lower RPMs.

This optimization is important because it means the engine can do its job effectively without wasting fuel or energy. In addition, optimizing the RPM range helps with the engine’s longevity. Running efficiently at lower speeds means less wear and tear over time, keeping the engine running longer.

Petrol Engines

RPM range optimization for petrol engines is about tuning these engines to perform well across a wide range of speeds. Petrol engines are designed to achieve their best performance at higher RPMs. This means they’re great for situations where quick acceleration and high-speed performance are desired, like in many passenger cars and sports vehicles.

Petrol engines shine when they’re revved up, delivering more power as the RPM increases. This is because their power output is closely linked to how fast they’re running. To make the most of this, engineers design petrol engines to be lightweight and to rev quickly, allowing them to reach their peak performance speeds in less time.

The goal with petrol engines is to offer a smooth and responsive driving experience, especially when you need quick acceleration. This requires careful design of the engine’s components, like the camshaft and intake system, to ensure they provide enough air and fuel to the engine at higher speeds.

Optimizing the RPM range in petrol engines also involves balancing fuel efficiency with performance. While these engines perform best at high RPMs, engineers also work to make sure they’re not wasting fuel, especially when driving at lower speeds or idling.

Emissions and Fuel Efficiency Considerations

Diesel Engines

When it comes to diesel engines, thinking about emissions and fuel efficiency is really important. Diesel engines are known for being more fuel-efficient than petrol engines. This means they can go further on the same amount of fuel, which is great for both your wallet and the environment.

However, diesel engines have a bit of a challenge with emissions. They tend to produce certain pollutants, like nitrogen oxides and particulates, which can be harmful to the air quality and people’s health. Because of this, there’s a lot of focus on making diesel engines cleaner.

Engineers work hard to improve how diesel engines burn fuel to reduce these emissions. This involves tweaking the engine design and using technology like exhaust after-treatment systems. These systems clean up the exhaust gases, removing a lot of the harmful pollutants before they leave the tailpipe.

At the same time, these improvements and technologies aim to keep the engine’s fuel efficiency high. It’s a delicate balance because sometimes making an engine cleaner can make it use more fuel. But, with advanced engineering and new technologies, modern diesel engines are becoming both cleaner and more efficient.

There are also strict laws about vehicle emissions, which help push manufacturers to keep improving their engines. These laws get tougher over time, so the work on making diesel engines better for the environment never really stops.

Petrol Engines

When we talk about petrol engines, emissions and fuel efficiency are key topics. Petrol engines have been the standard for most cars for a long time, mainly because they’re good at providing the power and speed drivers enjoy. However, like all engines, they have environmental impacts, primarily through emissions like carbon dioxide, which contributes to global warming, and other pollutants that can affect air quality and health.

Fuel efficiency in petrol engines is all about getting the most distance out of each liter of fuel. This not only saves money on fuel costs but also reduces emissions. Manufacturers have been making big strides in improving petrol engines to use fuel more efficiently and reduce emissions, using technologies such as direct fuel injection and turbocharging.

These technologies help the engine produce more power from less fuel and reduce wastefulness. Another significant focus has been on reducing the pollutants that petrol engines emit. This includes developing better catalytic converters, which are devices that clean up the exhaust gases before they leave the car, turning harmful pollutants into less harmful substances.

There’s also a big push to meet strict government regulations on vehicle emissions, pushing manufacturers to continually innovate and improve their engines. This includes developing hybrid systems that pair a petrol engine with an electric motor to offer even better fuel efficiency and lower emissions by relying on electric power at low speeds or when idling.

Despite these improvements, petrol engines still face challenges in reducing emissions and increasing efficiency compared to electric vehicles. However, ongoing advancements in engine technology and fuel formulations continue to make them more environmentally friendly.

These differences underscore the importance of camshaft design in engine performance, fuel efficiency, and emissions control. By understanding these distinctions, automotive engineers and enthusiasts can better appreciate how diesel and petrol engines are optimized for their specific operating principles and performance goals.