The camshaft is one of the most important moving parts in a diesel engine. It controls how the valves open and close. This action must happen at the right time and speed to keep the engine running smoothly. But none of that is possible without proper lubrication. A dry or under-lubricated camshaft can quickly wear down or fail. To avoid that, camshaft lubrication upgrades can make a big difference. From oil jets to improved flow rates, every detail matters. This article breaks it down in plain terms so you can protect your cam and boost engine reliability.

Why Camshaft Lubrication Matters

The camshaft sits at the top or middle of the engine block. It spins at half the speed of the crankshaft. As it turns, its lobes push against lifters, which control the valves. All this movement creates heat and friction. That’s where oil comes in. Engine oil forms a thin film that prevents metal-to-metal contact. Without this film, the camshaft grinds against other components. That leads to wear, heat buildup, and eventually failure.

In a diesel engine—especially a turbocharged one—everything runs hotter and under more pressure. That means the oil has to work even harder. If the oil doesn’t flow correctly to the camshaft or loses its protective qualities, trouble isn’t far behind. That’s why proper lubrication is not just helpful—it’s essential.

Understanding Oil Flow to the Camshaft

Oil reaches the camshaft through passages in the engine block. It flows under pressure from the oil pump. Some engines use splash lubrication, while others rely entirely on pressurized oil. The oil must reach every lobe, journal, and lifter. It also needs to be the right temperature and viscosity to do its job.

When flow is restricted, even for a few seconds, damage can occur. The cam lobes may start to score, pit, or gall. Journals can lose their round shape. Lifters can stick or collapse. This damage might not show up right away, but over time, it causes poor performance or total failure.

That’s why it’s important to check oil flow paths when building or upgrading an engine. Any restrictions, blockages, or undersized passages can rob the camshaft of the oil it needs.

What Are Oil Jets and How Do They Help?

Oil jets—or squirters—are small nozzles that spray oil onto specific engine parts. They’re often used to cool pistons, but they can also be aimed at the camshaft. This direct lubrication helps reduce wear on lobes and lifters. Oil jets deliver a controlled stream of oil right where it’s needed most. This reduces friction and keeps temperatures in check.

Adding oil jets to your lubrication system isn’t always easy. You may need to drill new passages or tap into existing ones. But the payoff is worth it—especially in high-performance or high-mileage diesel engines. Some aftermarket engine blocks or cylinder heads come pre-machined for oil jets. If your setup doesn’t include them, it might be time to consider this upgrade.

Proper placement is key. If the jet misses its target, the oil won’t do much good. You also need to make sure your oil pump can handle the extra demand. More jets mean more oil needs to flow. So balancing oil delivery and pressure is critical when adding these components.

High-Flow Oil Pumps and Camshaft Protection

One way to support better lubrication is by installing a high-flow oil pump. These pumps move more oil per revolution than stock units. This ensures every part—including the camshaft—gets the oil it needs, even under heavy load. High-flow pumps are especially useful in engines with tight bearing clearances, added oil jets, or larger capacity systems.

But high flow alone isn’t enough. You also need to maintain proper oil pressure. Too much flow with low pressure doesn’t protect well. Likewise, too much pressure can blow out seals or flood certain areas. That’s why many high-performance builds include adjustable oil pressure regulators. These allow fine-tuning of the system for maximum effectiveness.

The key is balance. You want steady, high-volume oil flow that maintains proper pressure through all RPM ranges. This setup ensures that the camshaft and other critical parts are always protected.

The Role of Oil Viscosity and Type

The type of oil you use plays a big role in how well your camshaft is lubricated. Diesel engines need oil that can handle high pressure and heat. That usually means a thicker viscosity like 15W-40 or 5W-40 for synthetic blends. Thicker oil forms a stronger film between moving parts. But it also needs to flow quickly at startup, when wear is most likely to occur.

Synthetic oils offer better performance at both high and low temperatures. They resist breakdown and keep their protective properties longer than conventional oils. For camshaft protection, synthetic oils with high levels of zinc (ZDDP) are ideal. Zinc helps protect metal surfaces under extreme pressure, like where cam lobes contact lifters.

Some newer oils have lower zinc levels due to emissions standards. This is fine for newer engines with roller lifters but can cause wear in flat-tappet designs. If you’re running a high-performance diesel or older engine, look for oils or additives that restore proper zinc levels.

Cam Journal Support and Upgrades

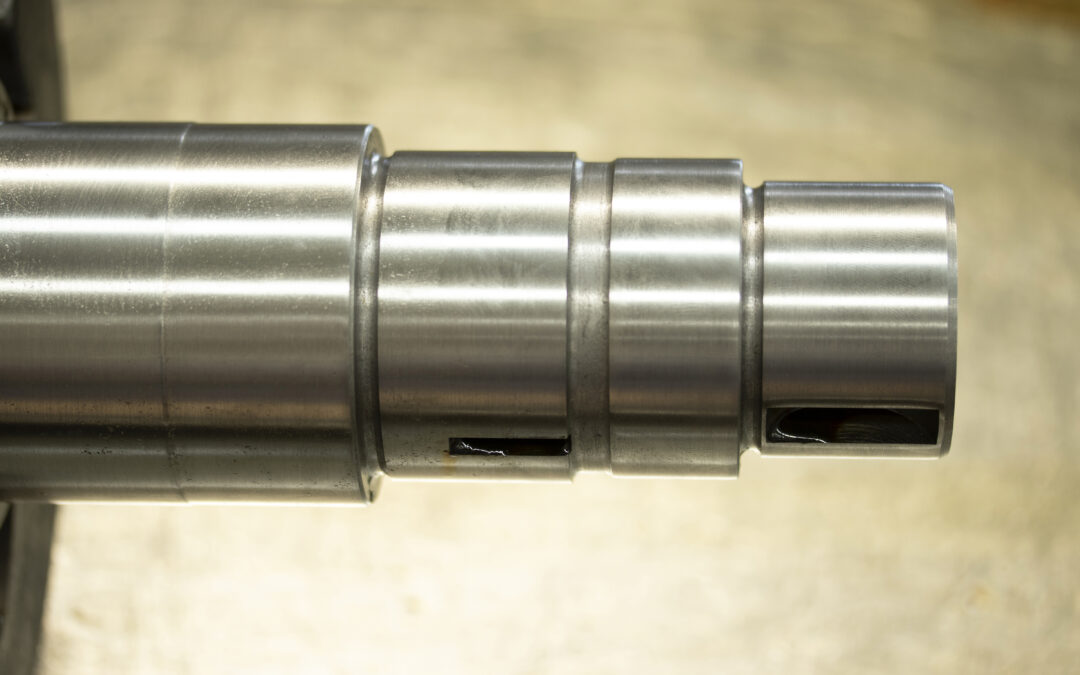

The journals are the round sections of the camshaft that rest in the engine block or cylinder head. They rotate in oil-filled bearings or bushings. If the oil film breaks down, these journals can wear down quickly. Worn journals cause poor valve timing, oil pressure loss, and eventual failure.

To prevent this, make sure journals are polished and round. Upgraded camshafts often come with hardened journals or special coatings. These features reduce friction and resist wear over time. Some builds use wider journals or additional bearings to spread out the load. This reduces localized pressure and keeps oil flowing evenly across the surface.

If you’re rebuilding an engine, always inspect the cam journals. Use a micrometer to check for wear or oval shapes. If journals are worn, you can sometimes repair them by grinding and using oversized bearings. If the damage is too great, replacement is the safer option.

Best Practices for Oil Analysis

Oil analysis is one of the best tools for monitoring camshaft wear. It involves sending a sample of used oil to a lab. The lab checks for metal particles, chemical changes, and signs of contamination. High levels of iron or other metals can point to camshaft wear. Contaminants like fuel or coolant may also show up and indicate other issues.

By performing oil analysis at regular intervals, you can spot problems early. It helps you track wear over time and make smarter maintenance decisions. For fleet vehicles or high-performance engines, oil analysis should be part of your routine. It gives peace of mind and prevents major failures by catching them before they happen.

Even without a lab, you can learn a lot by inspecting oil filters and drain pans. Look for metallic shimmer, sludge buildup, or unusual smells. These clues can tell you if your camshaft and other components are wearing faster than expected.

How to Build a Better Lubrication Strategy

Putting it all together, a strong lubrication strategy starts with the basics—good oil, regular changes, and steady pressure. From there, it includes upgrades like high-flow pumps, properly placed oil jets, and camshafts with treated journals. Don’t forget the value of matching parts. A high-lift cam with stock lifters and springs is a recipe for trouble. Every part must work together.

In short, you want oil to arrive fast, flow freely, and stay clean. That means keeping passages clear, oil levels correct, and using filters that catch fine debris. It also means avoiding long idle times, which reduce oil pressure and flow. Revving a cold engine is another mistake. Let it warm up so oil can reach every part before pushing it hard.

Final Thoughts

Camshaft failure is expensive and preventable. With the right lubrication upgrades, you can extend your engine’s life, improve performance, and avoid costly repairs. Oil jets, high-flow systems, strong journals, and good oil selection all work together to protect your investment. And by adding oil analysis into the mix, you gain visibility into your engine’s health before anything goes wrong. Whether you’re daily driving or running a performance build, camshaft lubrication should never be an afterthought. Treat it like the foundation it is, and your engine will thank you mile after mile.