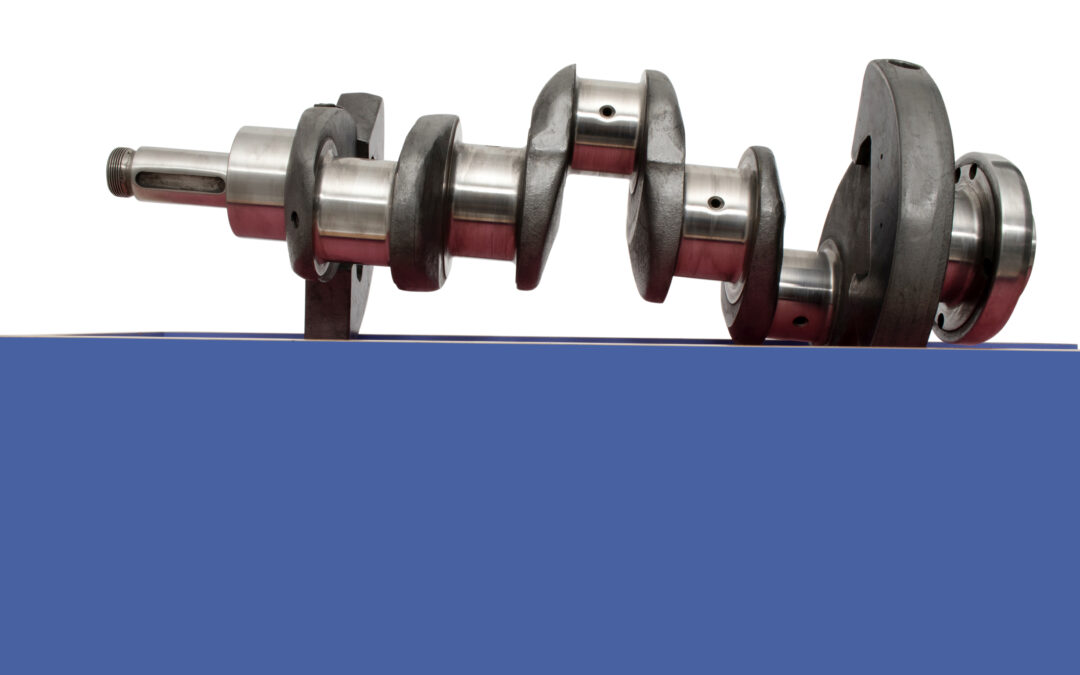

For an engine to run smoothly and efficiently, it needs to keep its internal components in perfect harmony, working together to convert fuel into power. At the heart of this operation is the crankshaft, responsible for translating the up-and-down motion of the pistons into rotational force that drives the wheels. However, as the crankshaft spins, it generates powerful forces that create vibrations throughout the engine. Left unchecked, these vibrations can lead to serious engine damage over time. This is where crankshaft dampers come into play, absorbing these harmful vibrations and helping keep the engine running smoothly.

In this article, we’ll explore what crankshaft dampers are, how they work, and why they’re essential for preserving engine health and improving longevity.

Understanding Harmonic Vibrations in the Engine

Before diving into crankshaft dampers, it’s essential to understand the issue they’re designed to solve: harmonic vibrations. Every time the pistons fire, they create pulses of force that are transferred to the crankshaft. At higher RPMs, these pulses can cause the crankshaft to twist slightly due to the intense forces involved. This twisting action, called torsional vibration, can create harmonic vibrations, which are repetitive, resonant vibrations that intensify at specific frequencies.

Think of harmonic vibrations as a guitar string: pluck the string, and it vibrates at a particular frequency. Similarly, when an engine’s RPMs reach a certain range, the torsional vibrations align in a way that causes them to resonate, amplifying the overall vibration. These vibrations don’t just make the engine noisier and rougher; over time, they can lead to wear on engine components, misalignment, or even crankshaft failure.

The Role of Crankshaft Dampers in Reducing Harmful Vibrations

A crankshaft damper, also known as a harmonic balancer, is specifically designed to minimize these harmful harmonic vibrations. Located at the front of the crankshaft, the damper acts as a buffer between the engine’s natural vibrations and the crankshaft, reducing the intensity of torsional vibrations as they build up. By absorbing and dissipating these forces, the damper keeps the crankshaft stable, allowing it to spin smoothly and helping to prevent premature engine wear.

The crankshaft damper generally consists of three main parts:

The Hub: This is the inner part of the damper that attaches directly to the crankshaft.

The Inertia Ring: Surrounding the hub is a metal ring, often made of iron or steel, that helps counterbalance the crankshaft’s rotation.

Damping Material: Sandwiched between the hub and inertia ring is a layer of rubber or a viscous fluid that absorbs vibrations. This damping material allows the inertia ring to move slightly, acting as a cushion against vibrations.

When the crankshaft twists and begins to vibrate, the damper’s inertia ring moves in the opposite direction to the vibration, effectively canceling it out. This opposite movement reduces the amplitude of the vibration, dampening the harmonic vibrations and helping the engine run more smoothly.

Types of Crankshaft Dampers and How They Work

There are several types of crankshaft dampers, each with a slightly different approach to managing vibrations. Let’s take a look at the main types:

Rubber Dampers: Rubber dampers are the most common type used in everyday vehicles. They rely on a rubber layer between the hub and inertia ring to absorb vibrations. This design is effective for standard engines but may wear out over time as the rubber hardens or deteriorates. Despite this, rubber dampers are a simple and cost-effective solution for most applications.

Viscous Dampers: Instead of rubber, viscous dampers use a silicone-based fluid between the hub and inertia ring. The fluid allows for more controlled, consistent damping, making viscous dampers especially effective for high-performance engines that experience intense vibrations. Viscous dampers are also durable, as the silicone fluid doesn’t wear out or degrade as easily as rubber, providing long-term reliability.

Fluidampr Dampers: Fluidampr dampers take viscous damping a step further with a sealed, maintenance-free design that provides even more effective vibration control. Inside, a thick silicone fluid surrounds an inertia ring that moves freely within the damper. This setup allows for optimal energy dissipation and is highly effective for racing engines or other high-performance applications.

Tuned Mass Dampers: Found in some high-end or racing engines, tuned mass dampers are carefully designed to counter specific frequencies of vibration. By adjusting the inertia ring’s mass and the damping material’s stiffness, engineers can tune the damper to cancel out vibrations at precise RPM ranges. This fine-tuning is useful for applications where engines frequently run at high RPMs and generate strong harmonic vibrations.

Benefits of Using a Crankshaft Damper

The primary job of a crankshaft damper is to minimize harmonic vibrations, but its benefits extend far beyond that. Here are some key advantages of using a crankshaft damper:

- Reduced Engine Wear and Tear: By absorbing vibrations, the crankshaft damper prevents excessive wear on engine components such as bearings, gears, and the crankshaft itself. This protection reduces the likelihood of premature failure, saving time and money on repairs.

- Enhanced Engine Longevity: With reduced vibrations, the entire engine experiences less stress and strain. This stress reduction leads to a longer engine life, which is particularly beneficial for high-performance or heavy-duty engines that operate under intense conditions.

- Improved Smoothness and Comfort: Vibrations can make an engine feel rough, affecting the overall driving experience. A crankshaft damper smooths out the engine’s operation, resulting in quieter, smoother performance that’s more comfortable for the driver and passengers.

- Better Fuel Efficiency: Excessive vibrations can lead to inefficiencies in the engine, including poor timing and increased friction. By dampening these vibrations, the crankshaft damper helps the engine maintain optimal timing and efficiency, which can result in improved fuel economy over time.

- Protection for High-Performance Engines: For high-performance and racing engines, crankshaft dampers are crucial. High RPMs amplify vibrations, and without a damper, these forces can quickly lead to catastrophic engine failure. Using a damper designed for high-stress environments, such as a viscous or Fluidampr damper, is essential for engines that frequently run at high speeds.

When Should You Replace a Crankshaft Damper?

Like any component, crankshaft dampers have a lifespan. Rubber dampers, for instance, are more susceptible to wear and may need to be replaced more frequently, especially if they show signs of cracking, hardening, or separation from the hub. Viscous and Fluidampr dampers are more durable but should still be inspected periodically, especially in high-performance or high-mileage engines.

Signs that it may be time to replace a crankshaft damper include:

- Excessive Engine Vibrations: If you feel more vibrations than usual, it could indicate that the damper is no longer absorbing vibrations effectively.

- Visible Wear or Damage: Check the damper periodically for signs of cracks, dents, or other visible damage.

- Unusual Engine Noises: Vibrations from a worn-out damper can create noises in the engine bay, often resembling rattling or knocking sounds.

- Increased Engine Wear: If components like belts, pulleys, or bearings are wearing out more quickly than usual, it may be due to increased engine vibrations from a failing damper.

Choosing the Right Crankshaft Damper for Your Needs

When selecting a crankshaft damper, consider the specific demands of your vehicle and driving style. Here are some general recommendations:

For Daily Drivers: A rubber damper is typically sufficient for standard engines in everyday cars. Rubber dampers are cost-effective and provide adequate vibration control for moderate RPM ranges.

For Performance Enthusiasts: For those with a performance engine or who regularly push their vehicle to higher RPMs, a viscous or Fluidampr damper is a better choice. These dampers offer superior durability and vibration control, especially for high-stress applications.

For Racing and High-Performance Builds: If you have a racing engine or a vehicle that frequently operates at high RPMs, consider a tuned mass damper or a premium Fluidampr model. These dampers are specifically designed to handle intense vibrations and offer precise vibration management.

Final Thoughts

Crankshaft dampers may be small, but they play a big role in maintaining engine health, preventing damage, and ensuring a smooth driving experience. By reducing harmonic vibrations, these dampers protect the crankshaft and other critical components from excessive wear and tear, ultimately extending the engine’s lifespan. Whether you’re driving a daily commuter or a high-performance machine, a quality crankshaft damper can make a noticeable difference in how your engine performs and how long it lasts.

Investing in the right crankshaft damper for your engine’s needs is a smart choice, one that helps you enjoy a smoother, more reliable driving experience, while also providing peace of mind that your engine is protected from harmful vibrations.