Bigger Turbos Bring Bigger Airflow Demands

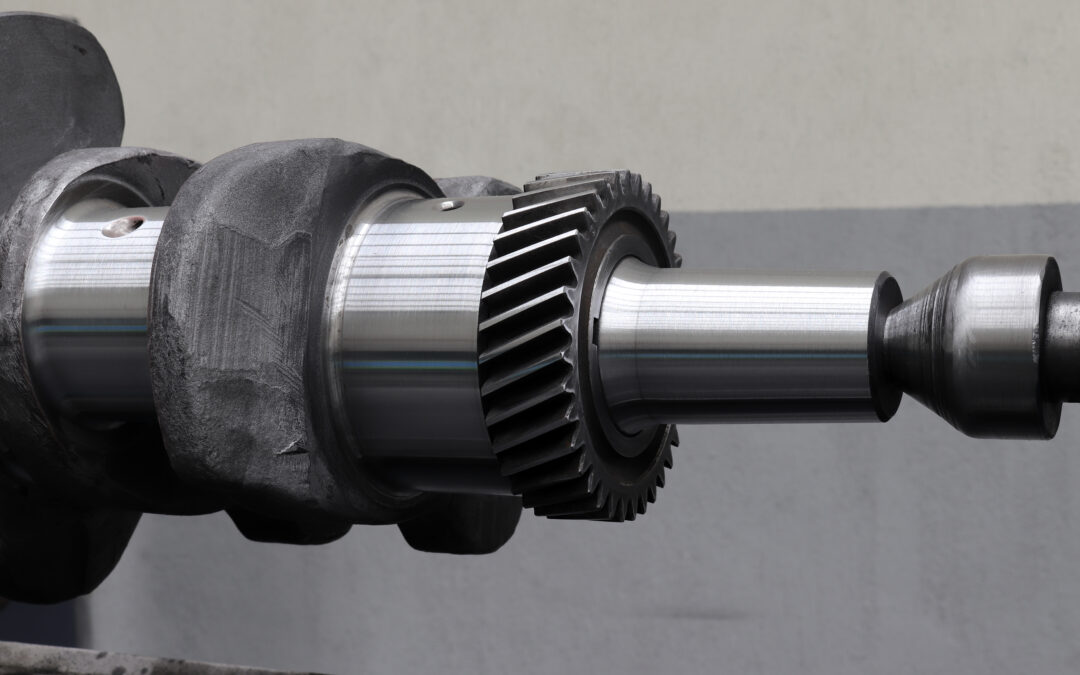

When upgrading a diesel engine with a larger turbo or a twin-turbo setup, many changes happen under the hood. These upgrades may seem like simple power boosts, but they create a ripple effect on how the engine operates. One of the most important areas impacted is the camshaft. This key component controls the timing and duration of the engine’s valve movements. With more air being forced in by the turbo, the camshaft needs to keep up. If it doesn’t, your engine might not perform as expected—even with an expensive new turbo setup.

Why Camshaft Timing Must Change

Turbo upgrades increase airflow into the combustion chamber. That means more oxygen, higher boost pressure, and potentially more fuel being burned. However, to fully use that extra air and fuel, the engine’s timing must be in sync. The camshaft is responsible for opening and closing the intake and exhaust valves at specific moments in the engine’s cycle. With more air being pushed in, the timing of those openings becomes more sensitive. The stock camshaft profile—designed for factory airflow—may now limit power instead of enhancing it.

Managing Boost Lag with Valve Timing Adjustments

A larger turbo or a twin-turbo system introduces something called “boost lag.” This is the slight delay between hitting the throttle and the turbo reaching peak boost. To help manage that delay and keep torque consistent, camshaft profiles are often adjusted. A performance camshaft can open the intake valves earlier or keep them open longer. This lets more air in at lower RPMs to help reduce lag and maintain engine responsiveness. This is just one way turbo upgrades and camshaft timing must work together.

Lift and Duration: Unlocking True Potential

Camshaft lift and duration are also critical factors to adjust. Lift refers to how far the valve opens, and duration is how long it stays open. With a stock cam, these numbers are usually conservative. That’s because manufacturers aim for fuel efficiency and emissions compliance. But when airflow increases due to a bigger turbo, these settings often become bottlenecks. Upgrading to a cam with higher lift and longer duration can take full advantage of the added boost. This change improves air intake, exhaust scavenging, and overall horsepower output.

Exhaust Timing and Backpressure Control

Exhaust valve timing becomes just as important as intake timing. More air in means more exhaust out. If the exhaust valve doesn’t open soon enough or long enough, backpressure can build up. That backpressure reduces turbo efficiency and limits how quickly the turbine can spool. In twin-turbo setups, this problem can multiply, especially in sequential systems. A performance camshaft ensures exhaust gases are cleared quickly and completely. That helps the turbos spin faster, reduce lag, and maintain steady boost levels.

Tuning Valve Overlap for Turbo Efficiency

Valve overlap is another part of the equation. This is the short moment when both intake and exhaust valves are open. In stock engines, overlap is minimal to avoid unburnt fuel escaping through the exhaust. But with turbocharged engines, controlled overlap can be beneficial. It allows the turbo to push in fresh air while clearing out exhaust gases. This improves cylinder filling and boosts power. However, too much overlap can cause problems like reversion or knock. A performance camshaft designed for turbo applications balances this overlap precisely.

Cylinder Pressure and Combustion Timing

Cylinder pressure is also affected by camshaft timing. When valves open or close too early or late, cylinder pressure can drop. This lowers power and can cause issues like misfires or poor fuel economy. A turbo adds more pressure by compressing intake air, but it needs precise valve timing to take advantage of it. Custom camshafts for turbo diesels are engineered to optimize pressure during compression and combustion. This ensures the engine runs smoother, with more torque and better throttle response.

Valve Train Durability Under Boost

Upgrading the camshaft isn’t just about matching airflow—it’s also about managing engine stress. More boost means more cylinder pressure, which puts more strain on the valve train. Stock camshafts and valve springs may not handle the added load, especially at higher RPMs. Upgraded components often include stronger cams, stiffer springs, and better followers. These parts ensure that valve timing remains stable, even under heavy boost and high-speed operation. Without them, the risk of valve float or timing issues increases dramatically.

Camshaft and Turbo Must Be in Sync

It’s important to understand that turbo upgrades and camshaft changes are part of a system. One affects the other, and both must work together. A mismatch between turbo size and camshaft profile can lead to poor performance, low fuel economy, or even engine damage. For example, a massive turbo paired with a stock cam might produce peak power at high RPMs only. That leaves low-end torque weak, making the engine feel sluggish. The goal is to match the cam to the turbo for usable power across the full RPM range.

ECU Tuning: The Final Piece of the Puzzle

Tuning also plays a huge role after camshaft and turbo upgrades. The ECU (Engine Control Unit) needs to be recalibrated to account for new timing, fuel delivery, and airflow. Without proper tuning, the engine may run lean or rich, which affects both power and reliability. Many tuners will use dyno sessions to dial in the timing maps, fuel trims, and boost curves. This helps make sure the new camshaft and turbo combo delivers safe, efficient, and powerful performance.

Different Turbo Setups, Different Cam Needs

Different turbo setups require different camshaft strategies. For example, a single large turbo might benefit from more valve duration to help with spool. In contrast, a twin-turbo system might be tuned for quicker response and mid-range torque. The camshaft profile needs to reflect those goals. Some builders even opt for variable valve timing systems, if available, to fine-tune cam timing across different RPM ranges. This dynamic control can help bridge the gap between low-end drivability and high-end power.

Diesel-Specific Considerations for Cam Upgrades

For diesel engines, which operate under high compression, camshaft changes must be even more precise. Unlike gas engines, diesels rely on compression ignition, not spark. So timing errors can cause serious problems, like hard starts or high exhaust temperatures. Custom cams for diesel applications are often tested thoroughly to ensure they don’t upset the balance of fuel, air, and compression. They’re designed with extra strength and specific timing maps to suit high-boost environments.

Conclusion: Camshafts Complete the Turbo Upgrade Equation

In the end, turbo upgrades can unlock a diesel engine’s hidden potential. But to reach that potential, the camshaft must evolve with the setup. A well-matched camshaft profile ensures that the extra air and fuel are used efficiently. It boosts power, improves response, and keeps the engine reliable under pressure. Skipping this step is like building a race car with a lawnmower transmission—it just won’t work together.

Final Thoughts: Don’t Overlook the Camshaft

If you’re planning to upgrade your diesel turbo setup, don’t overlook the camshaft. It’s a silent partner in the performance equation. Talk to a professional engine builder or camshaft specialist. Bring them your turbo specs, engine model, and performance goals. A properly selected camshaft upgrade will make your turbocharged diesel not just faster, but better all around. And that’s the kind of upgrade that pays off every time you hit the throttle.