Retrofitting Older Engines with DD15 Crankshaft Technology: A Path to Enhanced Performance

As technology continues to advance, older diesel engines might seem like relics of a bygone era. However, these workhorses still power countless trucks and heavy machinery around the world. With the rising costs of new equipment and the desire to extend the life of existing assets, retrofitting older engines with modern technology offers a compelling solution.

One such innovation that stands out is the DD15 crankshaft technology developed by Detroit Diesel. Retrofitting older engines with this cutting-edge crankshaft technology can breathe new life into aging machinery, offering benefits in performance, durability, and cost-effectiveness. Let’s explore the feasibility and advantages of this approach.

1. What is DD15 Crankshaft Technology?

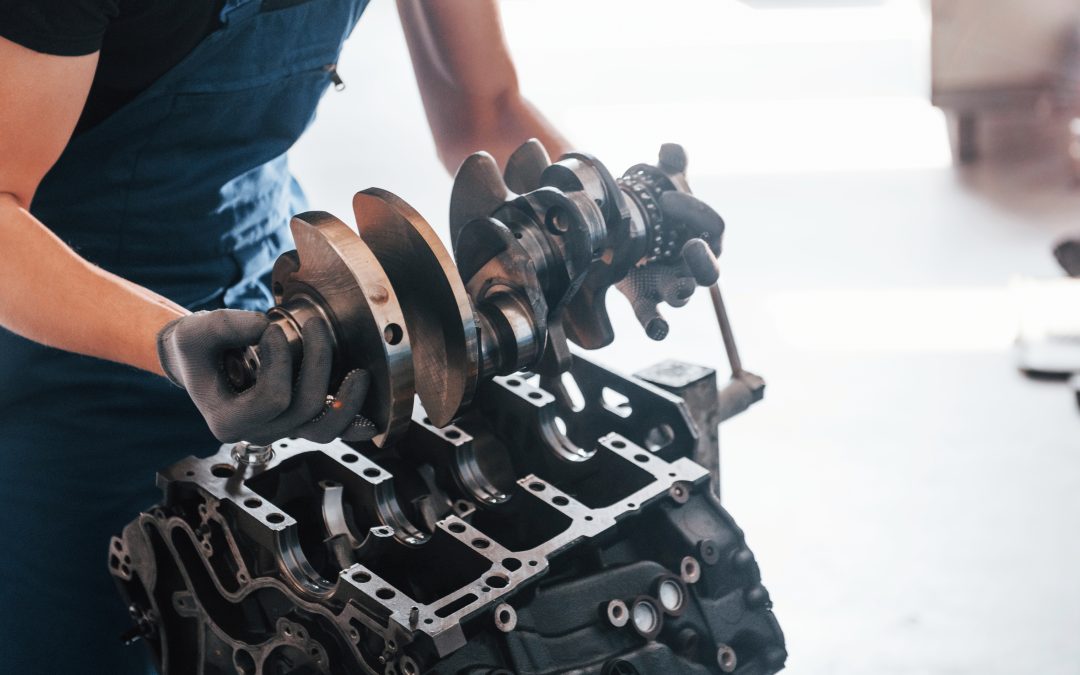

The DD15 engine by Detroit Diesel represents a significant leap forward in diesel engine design, with its crankshaft being a key component. The crankshaft is crucial in converting the pistons’ linear motion into rotational energy, which powers the vehicle. The DD15 crankshaft technology is renowned for its advanced materials, precision engineering, and optimized design, which all contribute to improved engine performance and longevity.

Advanced Materials

DD15 crankshafts are made from high-strength forged steel, which provides exceptional durability and resistance to wear and tear.

Precision Engineering

These crankshafts are designed with optimized geometry to minimize stress concentrations and reduce the likelihood of cracks and failures.

Microfinishing Techniques

The surfaces of DD15 crankshafts undergo microfinishing, creating a smooth finish that reduces friction, improves oil flow, and enhances overall efficiency.

2. Why Retrofit Older Engines?

Retrofitting older engines with DD15 crankshaft technology can be an attractive option for several reasons:

Cost Savings

Purchasing a new engine or vehicle can be a significant investment. Retrofitting allows owners to upgrade their existing engines at a fraction of the cost of a complete replacement. This can be particularly beneficial for fleet operators looking to improve performance without the capital expense of new equipment.

Extended Engine Life

By upgrading to more durable and efficient components, older engines can enjoy a new lease on life. This extends the useful lifespan of existing assets, delaying the need for replacement.

Improved Performance

Retrofitting with modern crankshaft technology can lead to better fuel efficiency, reduced emissions, and enhanced power output. These improvements can result in lower operating costs and compliance with stricter environmental regulations.

Environmental Benefits

Keeping older engines running efficiently reduces the environmental impact associated with manufacturing new engines. Retrofitting is an eco-friendly choice that minimizes waste and conserves resources.

3. Feasibility of Retrofitting with DD15 Crankshaft Technology

Before jumping into retrofitting, it’s essential to consider the feasibility of incorporating DD15 crankshaft technology into older engines. Here are some key considerations:

Compatibility

The first step is to assess whether the DD15 crankshaft can physically fit into the older engine’s block. This requires detailed measurements and engineering analysis. In some cases, modifications to the engine block, bearings, or other components may be necessary to accommodate the DD15 crankshaft.

Engineering Expertise

Retrofitting isn’t a simple swap. It requires expertise in both the old and new technologies. Collaborating with engineers who understand the intricacies of both systems is crucial to ensuring a successful retrofit.

Supply Chain

Access to DD15 crankshafts and compatible parts is another important factor. Working with suppliers who can provide the necessary components and support is essential for a smooth retrofitting process.

Regulatory Compliance

Depending on the region and application, retrofitting older engines may need to meet certain regulatory requirements. Ensuring that the retrofitted engine complies with emissions standards and safety regulations is vital to avoid legal issues.

4. Performance Enhancements from Retrofitting

The primary benefit of retrofitting older engines with DD15 crankshaft technology lies in performance enhancement. Here’s how the new crankshaft technology can make a difference:

Increased Durability

The high-strength forged steel used in DD15 crankshafts provides greater resistance to the stresses and strains of engine operation. This increased durability means the engine can withstand higher loads and harsh operating conditions without failing.

Reduced Vibration

The precision engineering of the DD15 crankshaft reduces vibrations within the engine. Lower vibrations lead to a smoother running engine, reducing wear on other components and improving overall vehicle comfort.

Improved Fuel Efficiency

The microfinishing techniques used on DD15 crankshafts result in smoother surfaces, which reduce friction. Less friction means less energy is wasted as heat, allowing more of the fuel’s energy to be converted into usable power. This leads to better fuel economy, which is a significant advantage for fleet operators looking to cut fuel costs.

Enhanced Power Output

With optimized geometry and reduced stress concentrations, the DD15 crankshaft allows for more efficient power transfer. This can lead to a noticeable increase in engine performance, providing more power and torque when needed.

5. Cost-Effectiveness of Retrofitting

While retrofitting older engines with DD15 crankshaft technology requires an upfront investment, the long-term cost benefits can be substantial:

Lower Maintenance Costs

A more durable crankshaft reduces the likelihood of engine failures and costly repairs. The enhanced reliability means fewer breakdowns and less downtime, keeping trucks on the road and generating revenue.

Fuel Savings

Improved fuel efficiency translates directly into cost savings at the pump. For trucks that travel long distances, even a small improvement in fuel economy can result in significant savings over time.

Extended Engine Life

By enhancing the engine’s core components, retrofitting extends its operational life. This delays the need for expensive replacements, spreading the investment over a longer period.

Increased Resale Value

Retrofitted engines with modern technology can be more attractive to potential buyers. The improved performance and reliability can increase the resale value of the vehicle or equipment.

6. Steps to a Successful Retrofit

To ensure a successful retrofit with DD15 crankshaft technology, consider the following steps:

Assessment

Start with a thorough assessment of the existing engine to determine compatibility and identify necessary modifications.

Expert Consultation

Work with experienced engineers or technicians familiar with both the older engine and DD15 technology. Their expertise will be invaluable in planning and executing the retrofit.

Sourcing Quality Parts

Ensure that all parts used in the retrofit are of high quality and compatible with the DD15 crankshaft. This includes bearings, seals, and other related components.

Installation

Follow precise installation procedures to ensure the crankshaft is correctly aligned and balanced. This will prevent premature wear and ensure optimal performance.

Testing and Calibration

After installation, thoroughly test the engine to confirm that it is running smoothly. Make any necessary adjustments to the engine’s calibration to optimize performance.

Regular Maintenance

Implement a regular maintenance schedule to monitor the retrofitted engine’s health. Early detection of potential issues will help prevent costly repairs and ensure long-term reliability.

Let’s Review

Retrofitting older engines with DD15 crankshaft technology offers a viable solution for enhancing performance, increasing durability, and achieving cost savings. While the process requires careful planning and expertise, the benefits can be substantial, making it a worthwhile investment for truck owners and fleet operators. By integrating modern technology into older engines, businesses can extend the life of their assets, reduce operating costs, and contribute to a more sustainable future. Whether you’re looking to boost power, improve fuel efficiency, or simply get more miles out of your existing engines, retrofitting with DD15 crankshaft technology is a strategy worth considering.