The Science Behind DD15 Crankshaft Material Choices: A Key to Performance and Longevity

When it comes to heavy-duty diesel engines like the DD15 from Detroit Diesel, the crankshaft is one of the most critical components. It converts the linear motion of the pistons into rotational motion that drives the vehicle. Given the immense stresses and strains that crankshafts endure, selecting the right materials for their construction is crucial.

The crankshaft materials used for DD15 are specifically chosen to enhance performance, durability, and longevity. In this blog, we will explore the science behind these material choices, why they are selected, and how they contribute to the overall effectiveness of the DD15 crankshaft.

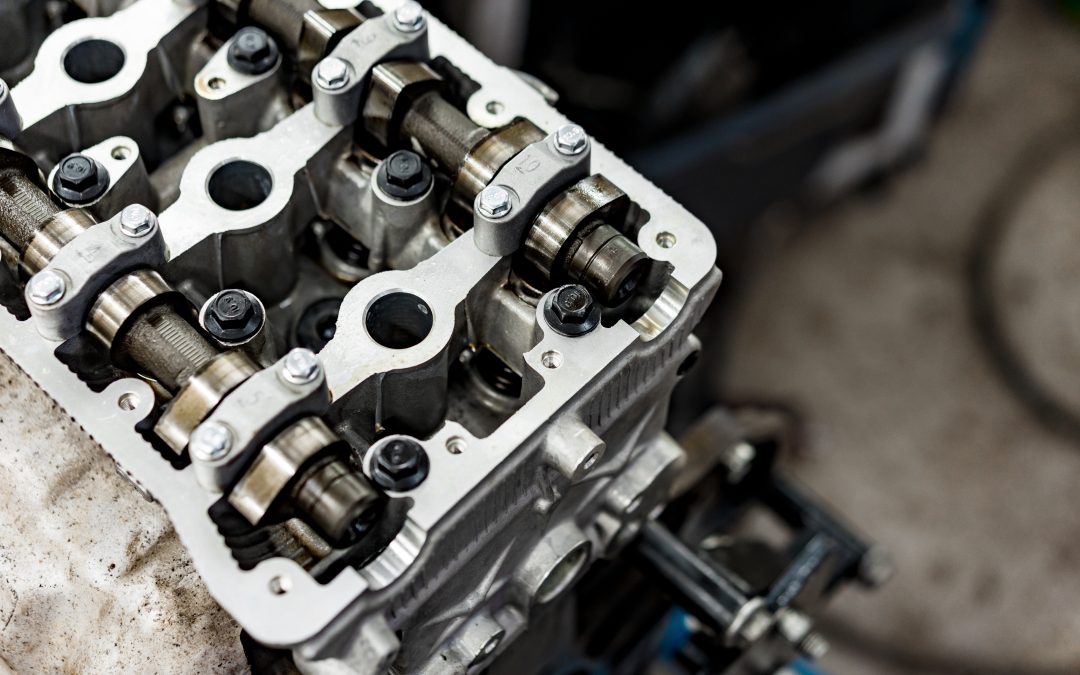

1. The Role of the Crankshaft in DD15 Engines

Before diving into the materials used, it’s important to understand the vital role of the crankshaft in the DD15 engine. The crankshaft sits at the heart of the engine, converting the up-and-down motion of the pistons into rotational energy that propels the vehicle forward. This component must withstand extreme forces, including high pressure from combustion, torsional stress from rotation, and bending forces as the pistons fire. A crankshaft that fails can lead to catastrophic engine damage, making material selection a top priority in its design.

2. Why Material Choice Matters

Choosing the right material for a crankshaft is essential for several reasons:

Durability

The crankshaft must be able to withstand high levels of stress and strain over long periods without cracking or breaking. Materials that offer high durability ensure that the crankshaft can endure the rigors of heavy-duty engine operation.

Strength

A strong material resists deformation under load. This is critical for maintaining the precise geometry of the crankshaft, which is necessary for optimal engine performance.

Fatigue Resistance

Crankshafts are subjected to repetitive stress cycles, which can lead to fatigue and failure. Materials that have high fatigue resistance can endure these cycles without degrading.

Weight

While strength and durability are important, the weight of the crankshaft also plays a role in engine performance. Lighter materials can reduce the overall weight of the engine, improving fuel efficiency and reducing the load on the vehicle.

3. Materials Used in DD15 Crankshafts

Detroit Diesel uses advanced materials for the DD15 crankshafts to meet the demanding requirements of heavy-duty diesel engines. The primary material used is forged steel, chosen for its superior strength, durability, and resistance to fatigue. Let’s look at why forged steel is the material of choice:

Forged Steel

Unlike cast iron or standard steel, forged steel is created by shaping the metal under extreme pressure, aligning the grain structure in the direction of the stresses the crankshaft will encounter. This process results in a denser, stronger material with fewer internal defects, such as air pockets or inclusions, that can weaken the crankshaft.

Alloy Additions

The steel used for DD15 crankshafts is often alloyed with other elements, such as chromium, molybdenum, and vanadium. These alloys enhance the steel’s properties, increasing its hardness, tensile strength, and resistance to wear and corrosion. For instance, chromium adds corrosion resistance, which is vital for protecting the crankshaft from the harsh environment inside an engine, where it is exposed to oil, fuel, and combustion gases.

Heat Treatment

After forging, the crankshaft undergoes heat treatment processes such as quenching and tempering. These processes harden the surface of the crankshaft, improving its wear resistance and enhancing its fatigue strength. Heat treatment helps create a hard outer surface with a tough, ductile core, providing a balance of strength and flexibility.

4. How Material Choices Enhance Performance

The materials selected for DD15 crankshafts directly contribute to the engine’s performance in several ways:

High Strength-to-Weight Ratio

Forged steel offers an excellent strength-to-weight ratio, meaning it provides the necessary strength without adding excessive weight. This balance is critical for heavy-duty engines, where excessive weight can negatively impact performance and fuel efficiency. A lighter crankshaft allows for faster engine response and acceleration, enhancing the overall driving experience.

Reduced Vibration and Noise

The high precision of forged steel, combined with its strength, allows for tighter tolerances in manufacturing. This precision reduces imbalances in the crankshaft, leading to less vibration and noise during engine operation. Lower vibration not only improves driver comfort but also reduces wear on other engine components, extending the engine’s life.

Improved Fuel Efficiency

The smooth surface finish achieved through microfinishing, combined with the lightweight nature of forged steel, reduces internal friction within the engine. Less friction means that more of the fuel’s energy is converted into usable power rather than being lost as heat. This efficiency improvement directly translates into better fuel economy, which is a significant advantage for fleet operators looking to reduce operational costs.

Enhanced Durability and Longevity

The durability of forged steel crankshafts means they are less likely to suffer from wear, cracks, or other forms of failure over time. The heat treatment and alloying elements further enhance this durability, providing resistance to the high temperatures and pressures inside the engine. A durable crankshaft means fewer engine failures, reduced maintenance costs, and longer engine life, all of which are critical for heavy-duty applications.

5. Impact on Engine Longevity

The choice of materials for the DD15 crankshaft directly impacts the overall longevity of the engine. By using forged steel with advanced alloys and heat treatments, Detroit Diesel ensures that the crankshaft can endure the rigors of heavy-duty operation. This longevity reduces the frequency of engine rebuilds or replacements, which can be costly and time-consuming. It also means that trucks can spend more time on the road, delivering goods and generating revenue, rather than in the shop for repairs.

6. Future Developments in Crankshaft Materials

While forged steel remains the gold standard for crankshaft construction, ongoing research and development are exploring new materials and manufacturing techniques. Advances in materials science could lead to even stronger, lighter, and more durable crankshafts in the future.

For example, the use of composite materials or advanced alloys could further reduce weight while maintaining or even enhancing strength. These innovations could push the boundaries of engine performance, making future diesel engines even more efficient and reliable.

7. Practical Considerations for Maintenance and Repair

Understanding the materials used in DD15 crankshafts also informs maintenance and repair practices:

Regular Inspections

Even with the best materials, regular inspections are crucial to catch any signs of wear or damage early. Look for indications of cracking, corrosion, or abnormal wear patterns, which could signal underlying issues.

Proper Lubrication

Using the right type of oil and maintaining proper oil levels is essential to protect the crankshaft. High-quality oil reduces friction and helps dissipate heat, minimizing the risk of wear and corrosion.

Timely Repairs

If any issues are detected, address them promptly. Delaying repairs can lead to more significant problems and higher costs in the long run.

In summary

The science behind DD15 crankshaft material choices underscores the importance of selecting the right materials for optimal engine performance and longevity. By using forged steel, advanced alloys, and heat treatment processes, Detroit Diesel has created a crankshaft that is strong, durable, and efficient.

These material choices not only enhance the engine’s performance but also reduce maintenance costs and extend the engine’s life. As technology continues to evolve, the future of crankshaft materials looks promising, with potential for even greater improvements in strength, weight, and durability. For now, the DD15 crankshaft stands as a testament to the power of material science in driving the evolution of diesel engine technology.